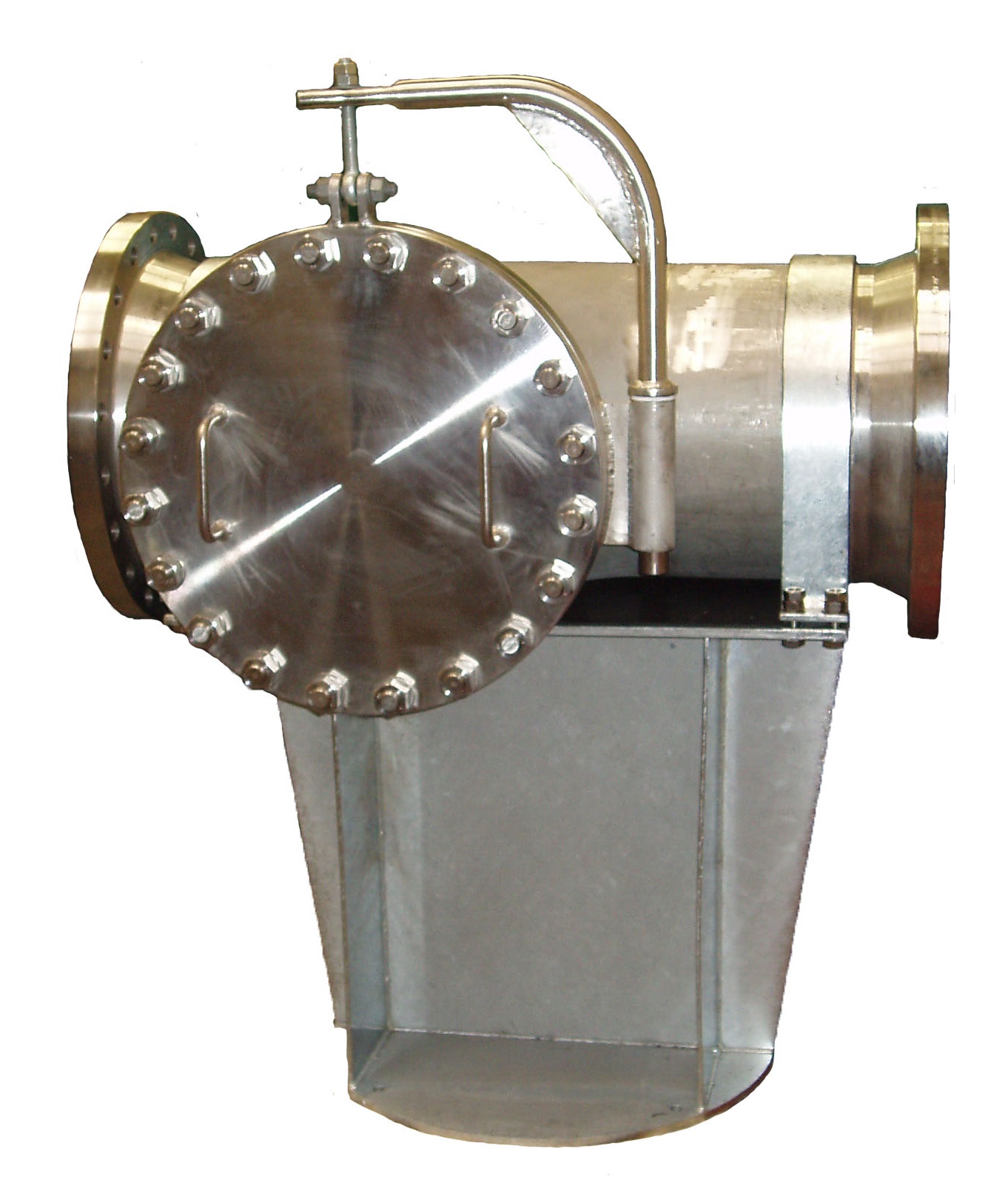

Bath Tub (T-Type) Temporary Strainer

Bath Tub Strainers are usually installed into ‘T’ junctions within pipework, which cannot normally be split to extract the basket after commissioning is complete. Access to the basket is via a blind cover or quick release closure. The basket is located and supported within the Tee by a runner bar system. Baskets can be supplied separately to client specification or the preferred method is for GFSA to supply the complete unit including the housing incorporating either butt-weld or flanged connections.

Bath Tub Strainers can be installed either in vertical or horizontal pipelines, in the vertical position the flow must flow downwards into the basket. In the horizontal position the branch connection is positioned on the side for side access or alternatively at the top for top access. Bath Tub Strainers are really restricted to course filtration because the way the basket is mounted inside the Tee could allow by-pass of fluid through the runner bar system.

Repeatability and interchangeability of baskets is very difficult because of the pipe fitting manufacture of equal tees, which is not consistent. Therefore, each basket is manufactured to each tee, and a record kept for future spare requirements. However, this type of strainer is widely used throughout the petrochemical industry and used as both a temporary and permanent strainer, although primarily they are classed as a temporary strainer.

Advantages

- Larger filtration areas than witch hat or top hat strainers, allowing higher flow rates and lower pressure differentials

- Straight through flow configuration

- Ease of installation and maintenance - no need to beak into the pipeline

- Retains contaminant

- Low capital cost - economical compared to large diameter Y-Type strainers

Disadvantages

- Restricted to course filtration

- Repeatability of manufacture and interchangeability of basket elements is limited due to inconsistent pipe fitting manufacture.

- Filtration area is limited to the pipe size and standard fittings used

Size range: From 2” nb to 48”n.b.

Pressure ratings: up to 2500LB.

A vast selection of materials of construction are available including:

- Carbon Steel

- Low temperature Carbon Steel

- Various grades of Stainless Steel, Duplex and Super Duplex Stainless Steel, 6 Mo Stainless Steel, Inconel, Hastelloy and Titanium.